Description

Specification

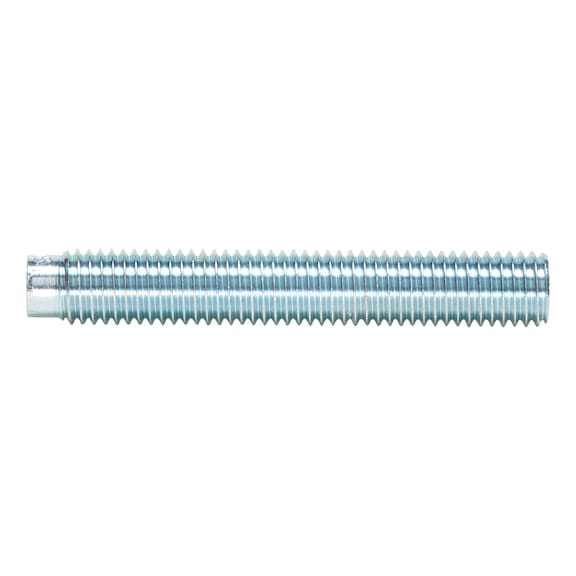

For injection systems Allrounder WIT-VM 250, masonry with perforated sleeve SH, Concrete Multi WIT-UH 300 and Pure Epoxy WIT-PE 1000. Zinc-plated steel | The anchor rod is covered by the following approvals/assessments: | Injection system ALLROUNDER WIT-VM 250, masonry: ETA-16/0757, ETA-20/0854

Injection system WIT-Nordic, masonry: ETA-16/0757

Injection system CONCRETE-MULTI WIT-UH 300, OPTION 1: ETA-17/0127

Injection system PURE-EPOXY WIT-PE 1000, OPTION 1: ETA-19/0542 | Injection system ALLROUNDER WIT-VM 250, masonry: ETA-16/0757, ETA-20/0854 | Injection system WIT-Nordic, masonry: ETA-16/0757 | Injection system CONCRETE-MULTI WIT-UH 300, OPTION 1: ETA-17/0127 | Injection system PURE-EPOXY WIT-PE 1000, OPTION 1: ETA-19/0542

Application

Application area | Can be used for the following injection systems: | Injection system ALLROUNDER WIT-VM 250, masonry (SH) – solid brick and perforated brick, aerated concrete

Injection system WIT-Nordic, masonry (SH) – solid brick and perforated brick, aerated concrete

Injection system CONCRETE-MULTI WIT-UH 300, cracked and uncracked concrete

Injection system PURE-EPOXY WIT-PE 1000, cracked and uncracked concrete | Injection system ALLROUNDER WIT-VM 250, masonry (SH) – solid brick and perforated brick, aerated concrete | Injection system WIT-Nordic, masonry (SH) – solid brick and perforated brick, aerated concrete | Injection system CONCRETE-MULTI WIT-UH 300, cracked and uncracked concrete | Injection system PURE-EPOXY WIT-PE 1000, cracked and uncracked concrete | W-VI-IG/S (zinc-plated steel) can be used in dry indoor areas

Tehnical Information

Type description: W-VI-IG/S | Female thread: 20 mm | Length: 200 mm | Nominal drill-bit diameter (d 0): 35 mm | Effective anchoring depth (h ef): 200 mm | Drill hole depth (h 0): 200 mm | Min./max. screw-in depth: 20-40 mm | Required injection mortar: WIT-UH 300, WIT-PE 1000 | Approval: ETA-17/0127, ETA-19/0542 | Material: Steel | Surface: Zinc plated