Description

Specification

for uncracked concrete, zinc-plated steel | Minimal effort required to insert anchor

Immediate load-bearing capacity — no waiting

No setting tools required

Can be set flush with surface: Attached parts can be removed/remounted at any time

Triple expansion sleeve to ensure even expansion and load distribution

Applying the specified torque during the anchoring process ensures secure installation

Load-controlled/torque-controlled expanding galvanised steel anchor in sizes M6–M12

Cotter-pin installation | Minimal effort required to insert anchor | Immediate load-bearing capacity — no waiting | No setting tools required | Can be set flush with surface: Attached parts can be removed/remounted at any time | Triple expansion sleeve to ensure even expansion and load distribution | Applying the specified torque during the anchoring process ensures secure installation | Load-controlled/torque-controlled expanding galvanised steel anchor in sizes M6–M12 | Cotter-pin installation | Proof of Performance | ETA-10/0255 for individual attachment, Option 7, non-cracked concrete, galvanised steel, M6–M12; dimensioned in accordance with the European Technical Approval Guidelines (ETAG) for “Metal Anchors for Use in Concrete”, Appendix C, measurement process A | Notice | The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of yF = 1.4 have been taken into account. Please refer to the European Technical Approval Guidelines (ETAG), Appendix C, for information on combining tensile and transverse loads, edge influence and groups of anchors. | The concrete has normal reinforcement. Higher values are possible for higher concrete strengths. | Compliant with approval if screws and threaded rods with acceptance test certificate 3.1 in accordance with EN 10204:2004 are proven to be the required material and to possess the mechanical properties stipulated in ETA-10/0255 | If a lower mounting height is required, make a deeper drill hole accordingly | Create the drill hole

Clean the drill hole

Knock in anchor until flush

Mount component

Apply torque | Create the drill hole | Create the drill hole | Create the drill hole | Clean the drill hole | Clean the drill hole | Clean the drill hole | Knock in anchor until flush | Knock in anchor until flush | Knock in anchor until flush | Mount component | Mount component | Mount component | Apply torque | Apply torque | Apply torque | ETA-10/0255 for individual attachment, Option 7, non-cracked concrete, galvanised steel, M6–M12; dimensioned in accordance with the European Technical Approval Guidelines (ETAG) for “Metal Anchors for Use in Concrete”, Appendix C, measurement process A

Application

Application area | Can be used for medium to heavy loads | Suitable for attaching: Transfer lines at floor level for which flush-mounted installation is specified; steel structures, metal profiles, brackets, base plates, cable ducts, pipelines, mounting rails etc. | The anchor has European Technical Approval for use in reinforced or non-reinforced standard concrete with strength class of minimum C20/25 and maximum C50/60 in accordance with EN 206:2000-12 | Can be used in concrete < C20/25, hard natural stone and solid brick masonry (without approval) | The anchor is approved for anchoring with predominantly static or quasi-static loads | Individual attachment: | Anchoring with European Technical Approval in non-cracked concrete | May only be used in dry indoor room conditions

Tehnical Information

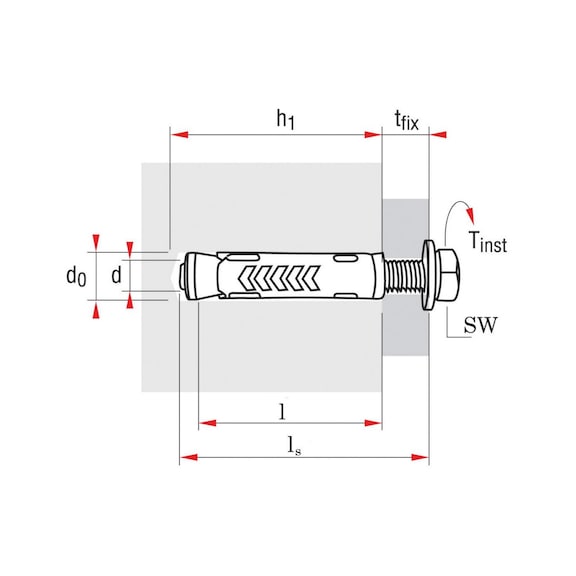

Anchor diameter: 8 mm | Anchor length (l): 51 mm | Max. attachment height (t fix): 14 mm | Nominal drill-bit diameter (d 0): 12 mm | Drill hole depth (h 1): 61 mm | Effective anchoring depth (h ef): 44.5 mm | Through-hole in the component to be connected (d f): 9 mm | Width across flats: 13 mm | Material: Steel | Surface: Zinc plated | Screw length: 65 mm