Description

Specification

Base mortar for masonry and uncracked concrete | Two-component reactive resin mortar, styrene-free polyester

Individual fixing point for uncracked concrete: | Two-component reactive resin mortar, styrene-free polyester | Individual fixing point for uncracked concrete: | W-VI-A anchor rod, W-VD-A anchor rod, standard threaded rod with acceptance test certificate 3.1 | Individual fixing point for masonry (system with SH perforated sleeve): | Individual fixing point for masonry (system with SH perforated sleeve): | W-VI-A anchor rod, standard threaded rod with acceptance test certificate 3.1, SH perforated sleeve | Proof of Performance | European Technical Assessment ETA-12/0569: Individual fixing point + uncracked concrete (W-VI-A anchor rod, W-VD-A anchor rod, standard threaded rod with acceptance test certificate 3.1)

European Technical Assessment ETA-13/0037: Individual fixing point + masonry (W-VI-A anchor rod, 3.1 standard threaded rod, SH perforated sleeve, autoclaved aerated concrete only without perforated sleeve)

EPD: Environmental product declaration in accordance with ISO 14025 and EN 15804 + A2, EPD-AWU-20230415-CBA2 | European Technical Assessment ETA-12/0569: Individual fixing point + uncracked concrete (W-VI-A anchor rod, W-VD-A anchor rod, standard threaded rod with acceptance test certificate 3.1) | European Technical Assessment ETA-13/0037: Individual fixing point + masonry (W-VI-A anchor rod, 3.1 standard threaded rod, SH perforated sleeve, autoclaved aerated concrete only without perforated sleeve) | EPD: Environmental product declaration in accordance with ISO 14025 and EN 15804 + A2, EPD-AWU-20230415-CBA2 | Application area | Wall units

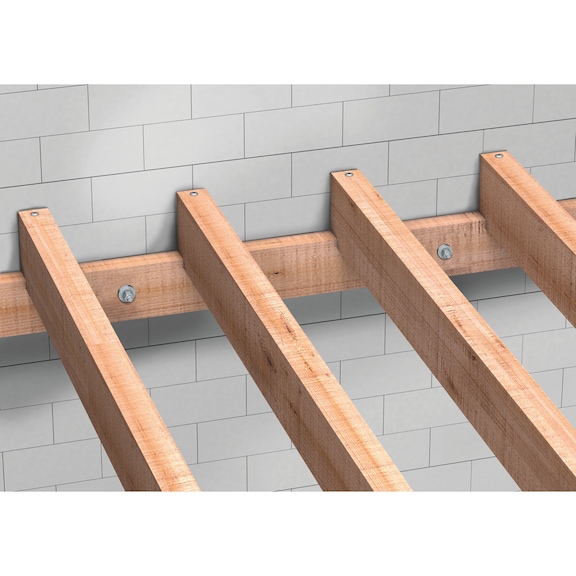

Wooden structures

Stairs | Wall units | Wall units | Wooden structures | Wooden structures | Stairs | Stairs | Drill holes with a rotary drill (without impact mechanism)

Clean drill hole; 2x blow out/2x brush out/2x blow out

Cut anchor rod to length and mark the desired insertion depths

Insert perforated sleeve

Screw mixer onto cartridge

Discard the first section of mortar (until the mortar is uniformly coloured – approx. 10 cm)

Completely fill with composite mortar from end of perforated sleeve

Press in anchor rod up to the bottom of the sleeve while turning slightly

Observe the injection mortar curing time

Mount component; do not exceed maximum torque | Drill holes with a rotary drill (without impact mechanism) | Drill holes with a rotary drill (without impact mechanism) | Drill holes with a rotary drill (without impact mechanism) | Clean drill hole; 2x blow out/2x brush out/2x blow out | Clean drill hole; 2x blow out/2x brush out/2x blow out | Clean drill hole; 2x blow out/2x brush out/2x blow out | Cut anchor rod to length and mark the desired insertion depths | Cut anchor rod to length and mark the desired insertion depths | Cut anchor rod to length and mark the desired insertion depths | Insert perforated sleeve | Insert perforated sleeve | Insert perforated sleeve | Screw mixer onto cartridge | Screw mixer onto cartridge | Screw mixer onto cartridge | Discard the first section of mortar (until the mortar is uniformly coloured – approx. 10 cm) | Discard the first section of mortar (until the mortar is uniformly coloured – approx. 10 cm) | Discard the first section of mortar (until the mortar is uniformly coloured – approx. 10 cm) | Completely fill with composite mortar from end of perforated sleeve | Completely fill with composite mortar from end of perforated sleeve | Completely fill with composite mortar from end of perforated sleeve | Press in anchor rod up to the bottom of the sleeve while turning slightly | Press in anchor rod up to the bottom of the sleeve while turning slightly | Press in anchor rod up to the bottom of the sleeve while turning slightly | Observe the injection mortar curing time | Observe the injection mortar curing time | Observe the injection mortar curing time | Mount component; do not exceed maximum torque | Mount component; do not exceed maximum torque | Mount component; do not exceed maximum torque | Create the drill hole

Clean drill hole; 2x blow out/2x brush out/2x blow out

Cut anchor rod to length and mark the desired insertion depths

Screw mixer onto cartridge

Discard the first section of mortar (until the mortar is uniformly coloured – approx. 10 cm)

Fill with composite mortar starting from the bottom of the drill hole (see enclosed leaflet)

Press in anchor rod up to the bottom of the sleeve while turning slightly

Visual check of mortar volume, embedment depth mark

Observe the injection mortar curing time

Mount component; do not exceed maximum torque | Create the drill hole | Create the drill hole | Create the drill hole | Clean drill hole; 2x blow out/2x brush out/2x blow out | Clean drill hole; 2x blow out/2x brush out/2x blow out | Clean drill hole; 2x blow out/2x brush out/2x blow out | Cut anchor rod to length and mark the desired insertion depths | Cut anchor rod to length and mark the desired insertion depths | Cut anchor rod to length and mark the desired insertion depths | Screw mixer onto cartridge | Screw mixer onto cartridge | Screw mixer onto cartridge | Discard the first section of mortar (until the mortar is uniformly coloured – approx. 10 cm) | Discard the first section of mortar (until the mortar is uniformly coloured – approx. 10 cm) | Discard the first section of mortar (until the mortar is uniformly coloured – approx. 10 cm) | Fill with composite mortar starting from the bottom of the drill hole (see enclosed leaflet) | Fill with composite mortar starting from the bottom of the drill hole (see enclosed leaflet) | Fill with composite mortar starting from the bottom of the drill hole (see enclosed leaflet) | Press in anchor rod up to the bottom of the sleeve while turning slightly | Press in anchor rod up to the bottom of the sleeve while turning slightly | Press in anchor rod up to the bottom of the sleeve while turning slightly | Visual check of mortar volume, embedment depth mark | Visual check of mortar volume, embedment depth mark | Visual check of mortar volume, embedment depth mark | Observe the injection mortar curing time | Observe the injection mortar curing time | Observe the injection mortar curing time | Mount component; do not exceed maximum torque | Mount component; do not exceed maximum torque | Mount component; do not exceed maximum torque | Create the drill hole

Clean drill hole; 2x blow out/2x brush out/2x blow out

Cut anchor rod to length and mark the desired insertion depths

Screw mixer onto cartridge

Discard the first section of mortar (until the mortar is uniformly coloured – approx. 10 cm)

Fill composite mortar from bottom of drill hole

Press in anchoring element up to drill hole base while turning slightly

Visual check of mortar volume, embedment depth mark

Observe the injection mortar curing time

Mount the component. Do not exceed the maximum torque | Create the drill hole | Create the drill hole | Create the drill hole | Clean drill hole; 2x blow out/2x brush out/2x blow out | Clean drill hole; 2x blow out/2x brush out/2x blow out | Clean drill hole; 2x blow out/2x brush out/2x blow out | Cut anchor rod to length and mark the desired insertion depths | Cut anchor rod to length and mark the desired insertion depths | Cut anchor rod to length and mark the desired insertion depths | Screw mixer onto cartridge | Screw mixer onto cartridge | Screw mixer onto cartridge | Discard the first section of mortar (until the mortar is uniformly coloured – approx. 10 cm) | Discard the first section of mortar (until the mortar is uniformly coloured – approx. 10 cm) | Discard the first section of mortar (until the mortar is uniformly coloured – approx. 10 cm) | Fill composite mortar from bottom of drill hole | Fill composite mortar from bottom of drill hole | Fill composite mortar from bottom of drill hole | Press in anchoring element up to drill hole base while turning slightly | Press in anchoring element up to drill hole base while turning slightly | Press in anchoring element up to drill hole base while turning slightly | Visual check of mortar volume, embedment depth mark | Visual check of mortar volume, embedment depth mark | Visual check of mortar volume, embedment depth mark | Observe the injection mortar curing time | Observe the injection mortar curing time | Observe the injection mortar curing time | Mount the component. Do not exceed the maximum torque | Mount the component. Do not exceed the maximum torque | Mount the component. Do not exceed the maximum torque | European Technical Assessment ETA-12/0569: Individual fixing point + uncracked concrete (W-VI-A anchor rod, W-VD-A anchor rod, standard threaded rod with acceptance test certificate 3.1)

European Technical Assessment ETA-13/0037: Individual fixing point + masonry (W-VI-A anchor rod, 3.1 standard threaded rod, SH perforated sleeve, autoclaved aerated concrete only without perforated sleeve)

EPD: Environmental product declaration in accordance with ISO 14025 and EN 15804 + A2, EPD-AWU-20230415-CBA2 | European Technical Assessment ETA-12/0569: Individual fixing point + uncracked concrete (W-VI-A anchor rod, W-VD-A anchor rod, standard threaded rod with acceptance test certificate 3.1) | European Technical Assessment ETA-13/0037: Individual fixing point + masonry (W-VI-A anchor rod, 3.1 standard threaded rod, SH perforated sleeve, autoclaved aerated concrete only without perforated sleeve) | EPD: Environmental product declaration in accordance with ISO 14025 and EN 15804 + A2, EPD-AWU-20230415-CBA2

Application

Application area | Attachment in uncracked concrete, solid and perforated brick masonry, aerated concrete

Suitable for attaching wooden structures, metal structures, metal profiles, brackets, grilles, sanitary ware, pipes, cable conduits, etc. | Attachment in uncracked concrete, solid and perforated brick masonry, aerated concrete | Suitable for attaching wooden structures, metal structures, metal profiles, brackets, grilles, sanitary ware, pipes, cable conduits, etc.

Tehnical Information

Type description: WIT-PM 200 | Contents: 300 ml | Included in delivery: Mortar cartridge 300 ml (tubular film) + 1 x mixer nozzle | Suitable application gun: Application gun MULTI, Application gun WIT 330ml, Silicone application gun 310ml | Min./max. processing temperature /conditions: -5 to 35 °C / temperature in the anchorage ground during processing and hardening | Min./max. ambient temperature / Conditions: -40 to 80 °C / after completely curing process | Temperature resistance, long-term temperatures max.: 50 °C | Temperature resistance, short-term temperatures max.: 80 °C | Shelf life from production/conditions: 12 Month / cool and dry storage area, 5°C to 25°C | Approval: ETA-12/0569, ETA-13/0037 | Chemical basis: Polyester, styrene free | Colour: Grey